Backflow Testing & Maintenance Services

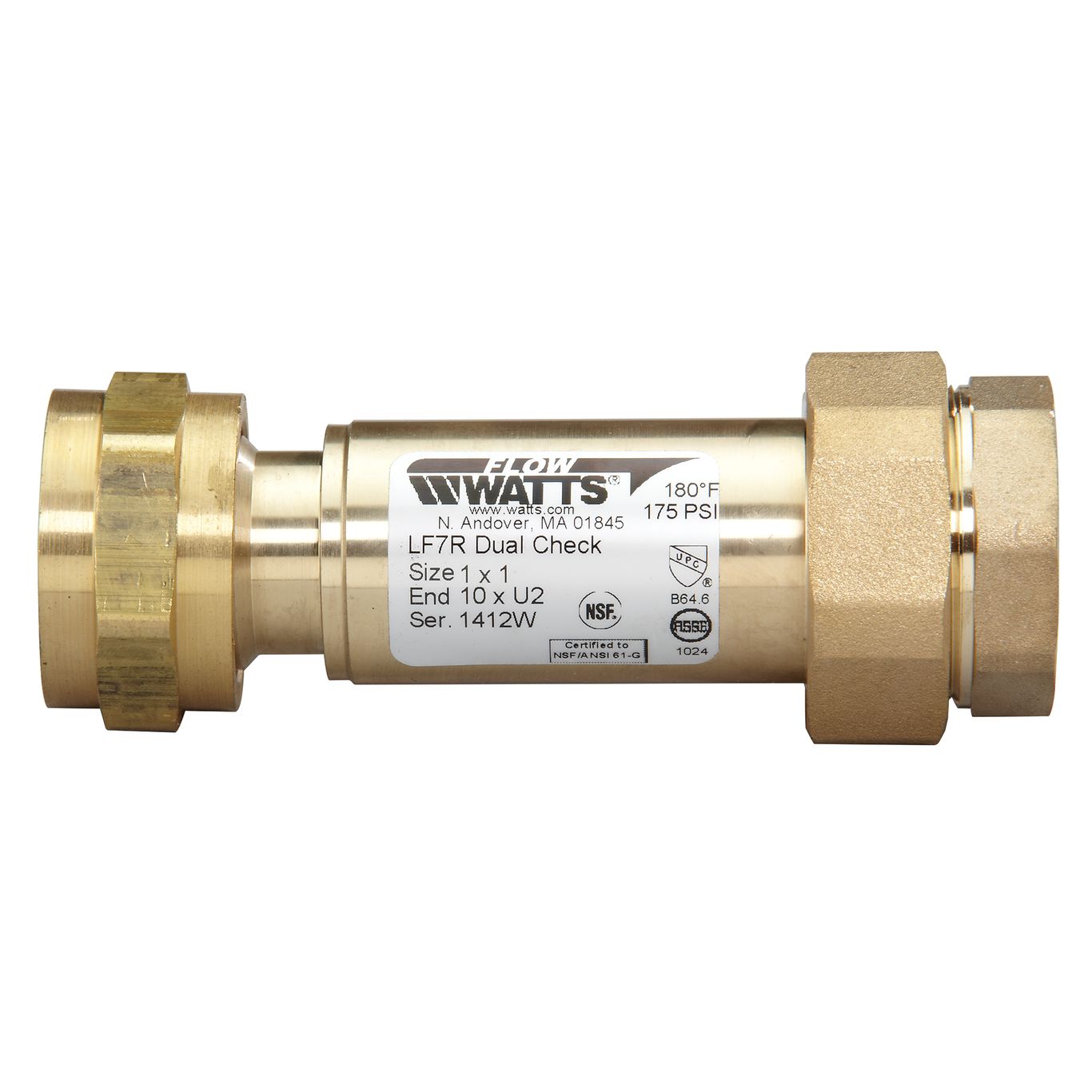

Pro Service Plumbing is a licensed & insured certified backflow installation and maintenance company. You can feel confident working with a team that is committed to getting the job done right the first time, and on time, everytime. We provide affordable backflow services, and you can have confidence in our AWWA Certified technicians. This qualifies us as one of the few companies able to test all backflow assemblies throughout South Florida.